More Methods

Laser Vs Other Sheet Metal Manufacturing Methods

There are several ways you can get this done — laser cutting, traditional shearing, waterjet cutting, and more — but how do you know which is right for your project? They each have unique advantages and disadvantages. While they are all good options for different applications, we are partial to laser cutting for reasons you will find out below!

First, here are a few of the main methods commonly used to cut sheet metal and other materials, along with some pros and cons.

Traditional Shearing

Mechanical cutting, or shearing, utilizes power-driven equipment to manually slice through sheet metal. Band saws, circular saws, lathes, drills, and milling machines are all examples of this.

The advantages of traditional shearing are that it is cheap, fairly accurate, and can cut a wide range of materials. For metals that are soft and sensitive to heat, thus prone to melting, this could be a good option. Mechanical tools such as lathes and milling machines are always an important part of an overall metal shop operation, since they are simple to use, especially for basic shapes and high volume operations.

However, mechanical shearing is less ideal for metals that are very hard, such as tungsten. Mechanical cutting can also create “burrs” and an unfinished look on the edge of the material being cut, or it can deform or crush the ends of tubes and other shapes where accuracy is important.

Waterjet Cutting

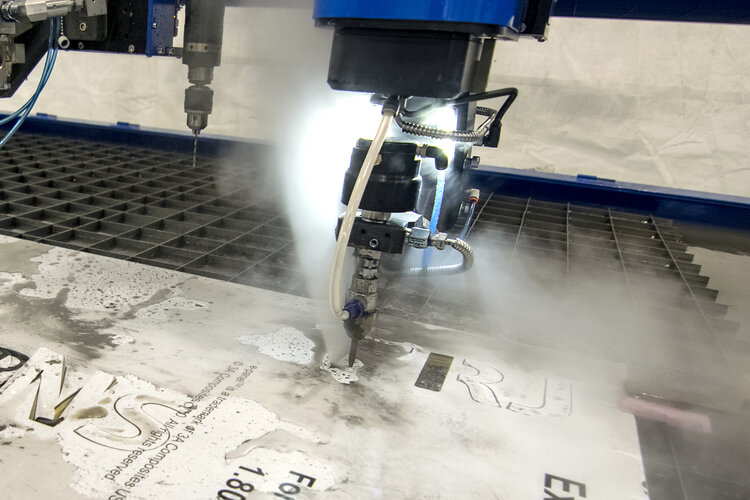

Waterjet cutting involves a high powered jet stream of water normally mixed with an abrasive like garnet powder to cut large, flat sheets of material. It is heat free, so it is normally used for heat sensitive materials like softer metals and plastics without warping or melting the products.

There are many downsides to water jet cutting. The water jet must be very close to the material — between 1 and 1.5 mm, which is impractical for anything 3D. The water stream is not always straight and accurate, since the water can “slide” around and make the cut edges tapered or uneven. The abrasive garnet powder is also very difficult to reuse which creates a lot of waste, and it can also make the finished surface dull and matte.

Laser Cutting

This method uses a tiny and very powerful laser that can cut with extreme accuracy and precision. Laser cutting is quick and perfect for custom designs, since there is no need for retooling and the end product is designed with a CAD program. Laser cutting causes no damage to the sheet metal, even very thin sheets. It can also use more of the actual sheet due to its tight tolerance space. This can lower costs and the amount of material used.

Because the laser “melts” the very end of the metal, the end product has a beautiful finished look, and the cuts are very straight and precise with little to no errors. This is perfect for any project that requires very tight tolerances, such as the aerospace industry, or small cuts like intricate designs on a sign or piece of art. When sheet metal needs to be cut, there is no job too complex for the laser cutting method.

Lastly, laser cutting is incredibly fast and versatile. It can cut almost any standard material, even very hard metals, and most standard thicknesses (exceptions being very thick or very soft materials which would be better suited to mechanical or waterjet methods). It can perform everything from etching and very tiny, intricate designs to large scale cuts of bigger pieces.

The only real downside to using laser cutting is that the high heat of the laser can sometimes emit fumes, depending on the type of material you are working with. However, with proper safety equipment and a well-ventilated shop, this can be easily dealt with.

Conclusion

As you can see, we believe that laser cutting can be a great option for most projects.